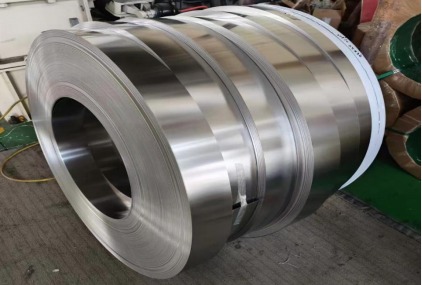

Stainless steel strip is playing a pivotal role in transforming the electronics industry, offering unparalleled benefits that enhance the performance, durability, and efficiency of electronic devices. As the industry continues to evolve, partnering with reliable stainless steel strip suppliers ensures access to high-quality materials that meet the demanding requirements of advanced electronics.

This article explores the various ways stainless steel strip is revolutionizing electronics, from manufacturing processes to end-user applications.

Superior Material Properties

- Corrosion Resistance:

- Longevity and Reliability:Stainless steel strip’s excellent corrosion resistance ensures the longevity and reliability of electronic components, especially in harsh environments. This property is crucial for devices exposed to moisture, chemicals, or extreme temperatures.

- Reduced Maintenance:The resistance to corrosion reduces maintenance needs, ensuring that devices remain operational for extended periods without requiring frequent repairs or replacements.

- Mechanical Strength:

- Durability:The high tensile strength of stainless steel strip provides robust support for electronic components, preventing deformation and damage during manufacturing and usage. This strength is particularly beneficial in applications requiring thin, yet strong materials.

- Flexibility:Despite its strength, stainless steel strip maintains a degree of flexibility, allowing it to be formed into intricate shapes without compromising structural integrity. This flexibility is essential for miniaturized electronic components.

Applications in Electronics

- Battery Components:

- Battery Casings and Terminals:Stainless steel strip is widely used in the production of battery casings and terminals, offering excellent conductivity and corrosion resistance. This ensures efficient power transfer and longevity of batteries in devices like smartphones, laptops, and electric vehicles.

- Advanced Battery Technologies:With the rise of renewable energy storage and electric vehicles, stainless steel strip plays a crucial role in advanced battery technologies, including lithium-ion and solid-state batteries.

- Connectors and Contacts:

- High Conductivity:Stainless steel strip’s high electrical conductivity makes it ideal for connectors and contacts in electronic devices. These components require reliable and consistent performance to maintain the integrity of electrical connections.

- Miniaturization:As electronic devices become smaller, the demand for miniaturized connectors and contacts increases. Stainless steel strip’s strength and formability make it suitable for these applications, ensuring durability and performance in compact designs.

- Shielding and Enclosures:

- Electromagnetic Interference (EMI) Shielding:Stainless steel strip is used in shielding applications to protect electronic components from electromagnetic interference. EMI shielding is essential in maintaining the functionality and reliability of sensitive electronics.

- Durable Enclosures:The use of stainless steel strip in enclosures provides robust protection for electronic devices, safeguarding them from physical damage and environmental factors.

Benefits for Manufacturers and End Users

- Cost-Effectiveness:

- Efficiency in Production:Stainless steel strip’s properties allow for efficient manufacturing processes, reducing production costs and increasing yield rates. This efficiency benefits manufacturers by lowering operational costs and improving profit margins.

- Long-Term Savings:For end users, the durability and low maintenance requirements of stainless steel strip translate to long-term savings. Devices last longer and require fewer repairs, providing excellent value over their lifespan.

- Environmental Impact:

- Sustainability:Stainless steel strip is highly recyclable, making it an environmentally friendly choice for electronic components. Recycling stainless steel reduces the need for virgin materials, conserving natural resources and minimizing environmental impact.

- Compliance with Regulations:The use of stainless steel strip helps manufacturers comply with environmental regulations and standards, promoting sustainable practices in the electronics industry.

Conclusion

Stainless steel strip is revolutionizing the electronics industry by offering unmatched benefits in terms of durability, performance, and sustainability. Its application in battery components, connectors, shielding, and enclosures highlights its versatility and importance in modern electronic devices.By sourcing from reputable stainless steel suppliers, manufacturers can ensure the reliability and longevity of their electronic components.